Shipping container condensation is a major problem for different types of nut cargo.

For example, peanuts are shipped from major growing regions in South America and the USA to destinations in Asia and Europe. Risk factors such as the moisture content of the product and the nature of international shipping routes mean that peanuts are susceptible to cargo moisture damage.

When it comes to peanut shipments, cargo moisture damage can lead to problems such as mold which make the goods unfit for consumption.

The same is true for other nut products, with goods such as cashews, hazelnuts, pecans and walnuts at an elevated risk of shipping container condensation.

Why are the Vdry products popular to prevent cargo moisture damage

The Vdry range widely used to protect shipments of different nut products against shipping container condensation.

This includes three key products that work in harmony to protect cargo in different ways against cargo moisture damage.

Investigation into cargo moisture damage in peanut shipments

To achieve deeper insights into how the Vdry products can minimize shipping container condensation in nut shipments, we teamed up with a major Argentinian peanut exporter.

A 40’ container was loaded in the Cordoba province in Argentina with 20 tote bags each containing 1.25 tons of shelled runner peanuts. This container was shipped to Rotterdam in the Netherlands.

The container was packed with three Vdry products to protect against cargo moisture damage:

- Vdry Bag: high-performance desiccant bags to absorb humidity from the container atmosphere. This reduces the relative humidity and lowers the risk of condensation forming.

- Vdry Blanket: absorbent blanket which hangs over cargo to protect against any condensation that forms on the container ceiling. This is an essential solution to keep goods dry.

- Vdry Liner: a water-resistant and breathable lining to protect goods against condensation and contamination on the container walls and floor.

Data loggers were used to analyze the temperature and humidity levels inside the container.

How the Vdry products protected against shipping container condensation

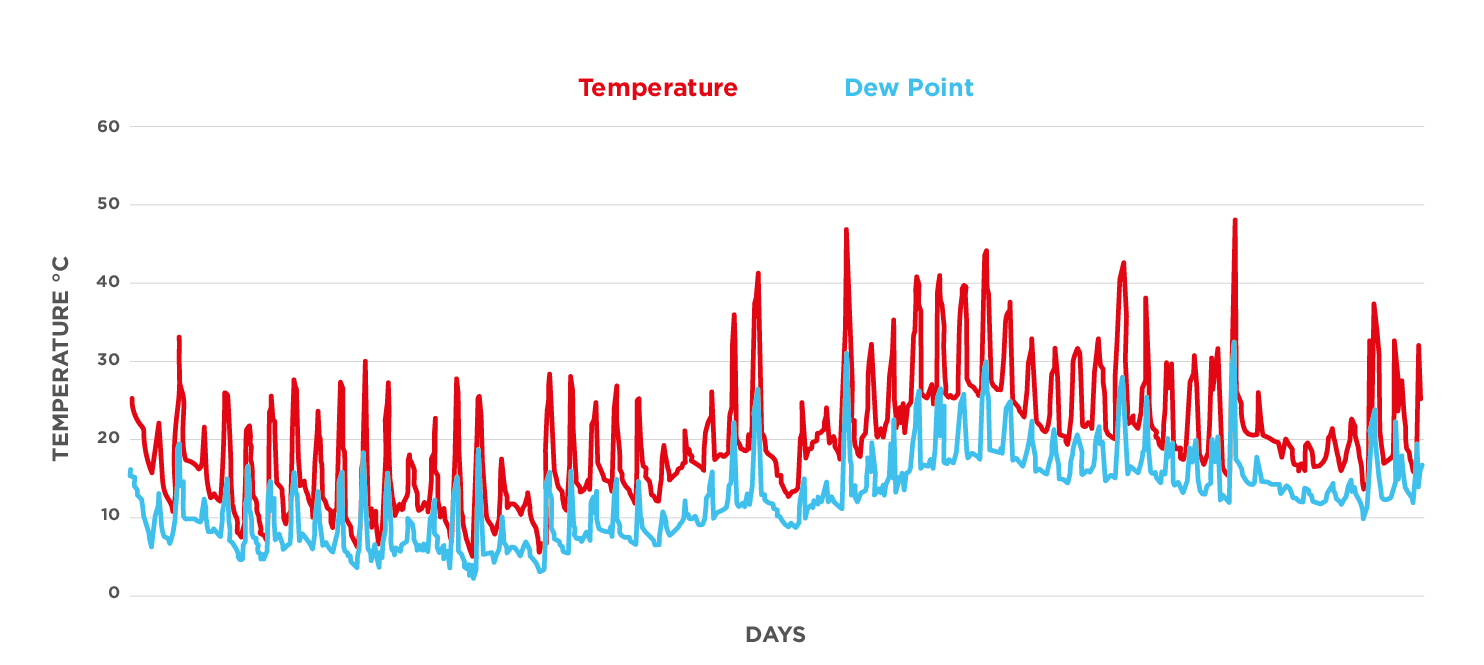

The data logger results showed frequent temperature fluctuations during the voyage, with peaks reaching 48°C.

It is visible in the graph (below) that there are regular periods at which the temperature reaches dew point. This is the point at which shipping container condensation forms, and means that there were extended periods in which the goods were at risk of cargo moisture damage.

Despite the consistent risk of shipping container condensation, there were no signs of cargo moisture damage.

The investigation highlights why the Vdry products are an essential choice to protect nut shipments against cargo moisture damage.

Conclusion – how you can prevent shipping container condensation in your nuts shipments

Given the increased risk of shipping container condensation in nut shipments, high-performance solutions, such as the Vdry products, are essential to minimize the risk of cargo losses.

As we saw in the study, the three Vdry products work in harmony to protect against cargo moisture damage in different ways.

The leakproof Vdry Bag desiccants absorb humidity from the air to lower the dew point inside the container. The Vdry Blanket provides essential covers against any condensation that forms on the ceiling, while the Vdry Liner acts as a water-resistant barrier on the walls and floor.