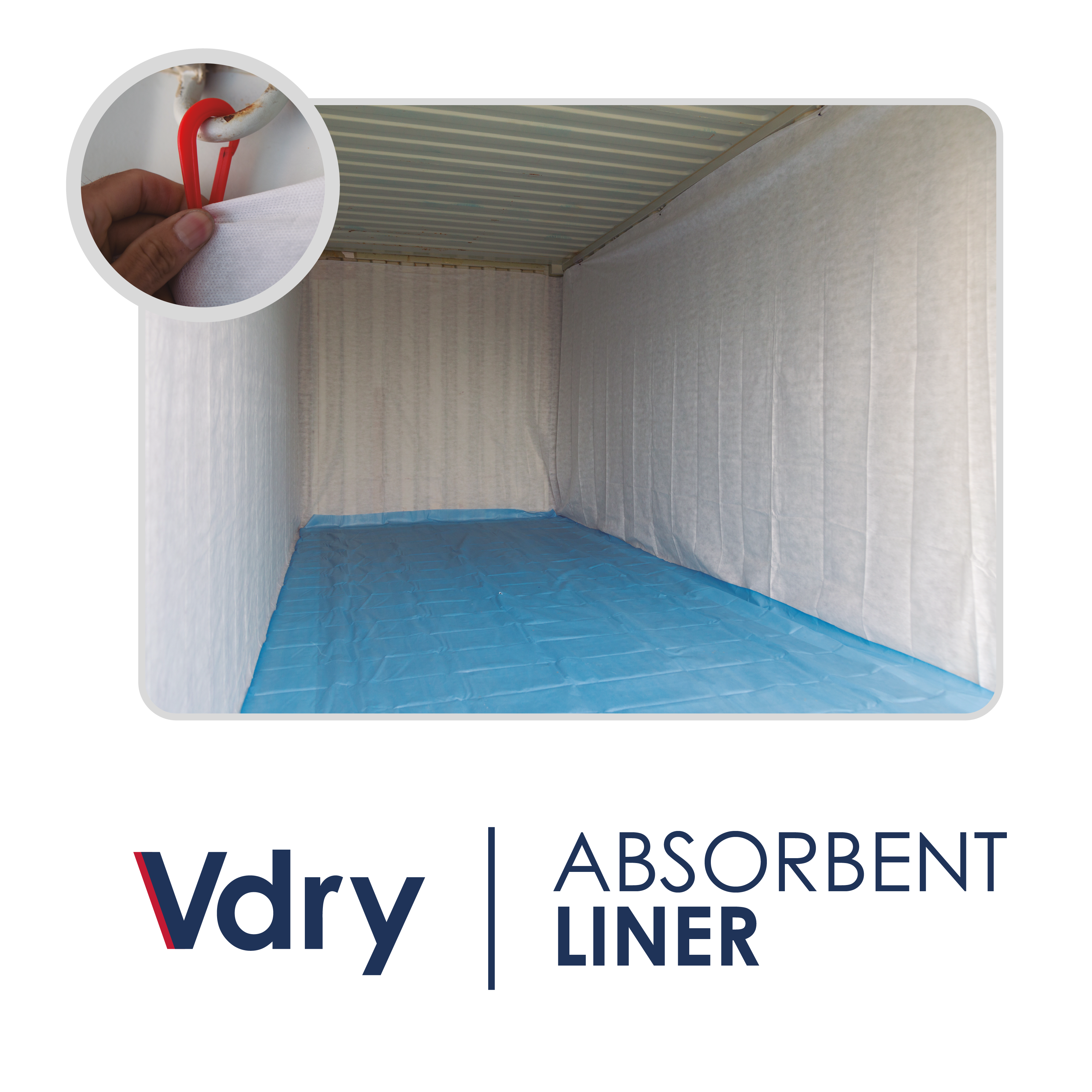

Vdry Desiccant Bags are a premium line of high-performance container desiccants designed to prevent moisture damage during shipping and storage. Combining maximum absorption capacity with leakproof technology, Vdry Bags deliver unparalleled protection for cargo across a range of industries, including agriculture, chemicals and electronics.

To meet the unique needs of different shipments, Vdry Desiccant Bags are available in multiple models, each designed with specific applications in mind. These models come in a variety of shapes, sizes, and specifications, allowing shippers to select the optimal desiccant solution based on cargo type, transit conditions, and storage requirements.

Why Choose Vdry Desiccant Bags?

The Vdry Desiccant Bags are favored by global shippers for their unrivaled absorption capacity and leakproof characteristics to prevent moisture damage inside shipping containers. Available in a variety of models and specifications, the Vdry Desiccant Bag range helps shippers overcome a variety of cargo shipping challenges.

The Vdry Absorbent Bags offer

Maximum absorption

Our advanced gel formulas, developed in state-of-the-art laboratories, ensure unparalleled moisture absorption to prevent damage to cargo in shipping.

Leakproof techonology

Precision manufacturing eliminates leaks, even under high humidity even when the bags are at maximum capacity.

Fast installation

Install any of our desiccant bags for shipping containers in seconds to save valuable time.

Breathtaking breathability

Engineered materials ensure rapid absorption, ideal for even the most humid environments.

Non-toxic & safe

Manufactured with eco-friendly, non-toxic materials, ensuring safe use in food, pharmaceuticals, and other sensitive industries.

Explore the Full Range of Vdry Desiccant Bags

Each Vdry Desiccant Bag model is designed to meet specific shipping and storage needs, offering unparalleled container moisture protection. To ensure the best fit for various cargo types and transit conditions, these Desiccant Bags are available in multiple models, each offering different shapes, sizes, and specifications.

Whether you require compact absorbent bags for packaging, or large desiccant bags for shipping containers, Vdry provides tailored moisture control solutions to meet the specific requirements of different shippers.

features

Peerless absorption

We are constlanty improving our gel recipes to increase the capacity of the Vrdy Bag.

Zero leaking

The Vdry Bags are manufactured with premium materials and rigorously tested for their leak resistance.

Breathable membrane

Fast absorption of humid air is enhanced by materials that are handpicked for their breathability.

Easy handling

Available in a variety of specifications, the Vdry Bags facilitate easy handing and installation.

Non toxic

Materials are selected for their non toxicity and low environmental impact.

How Vdry Container Desiccants Work

The secret to the Vdry Bag’s popularity comes from an analytical combination of key features – unrivaled absorption in leakproof and easy-to-handle packages. This marriage of premium-grade characteristics means the Vdry Bag is the go-to container desiccant for shippers across high-risk industries around the world.

The benefits for shippers are clear – an immediate economic advantage in reducing cargo losses, and a competitive edge in a market in which moisture damage is a frequent problem.

The process is simple yet effective:

- Absorption: The breathable materials allow moisture to enter the bag, where it is quickly absorbed.

- Containment: The advanced gel traps humidity, preventing leaks or evaporation.

- Protection: Your goods remain safe from mold, rust, and other forms of moisture damage.

We continuously develop our high-performance gel mixes in our specialized laboratories to improve their capacity and better suit the needs of our customers.

How to Use Vdry Desiccant Packs

Effortless to use and highly effective, here’s how to make the most of Vdry Bags:

- Choose the right Vdry desiccant bag for your shipment’s needs.

- Place the bags strategically within the shipping container or packaging.

- Dispose Vdry desiccant bags in accordance with protocols at destination.

The Cost of Doing Nothing: Moisture Damage in Shipping

Moisture damage doesn’t just cost money—it costs trust. Late shipments, ruined goods, and client complaints can destroy reputations.

By investing in shipping container desiccant bags by Vdry, you can:

- Reduce expensive cargo losses.

- Avoid costly returns and insurance claims.

- Build a reputation as a reliable supplier who delivers undamaged products every time.

- Choose the right Vdry desiccant bag for your shipment’s needs.

- Place the bags strategically within the shipping container or packaging.

- Dispose Vdry desiccant bags in accordance with protocols at destination.

Your Guide to Cargo Desiccants

There are a lot of cargo desiccant bags on the market. But not all are created equal. Check out our guide to learn how to make smart desiccant decisions and reduce cargo moisture damage.

Example industries

Cocoa & Coffee

Protects cocoa and coffee from mold, spoilage, and humidity damage during long-haul shipments

Grains

Protects grains from mold, spoilage, and humidity damage during long-haul shipments

Nuts

Protects nuts from mold, spoilage, and humidity damage during long-haul shipments

Chemicals

Metals y Machinery

Pharmaceuticals

FAQs: Answering Your Desiccant Bag Questions

What are desiccant bags used for?

Desiccant bags are used to absorb moisture in shipping containers, storage boxes, and packaging, preventing damage to goods during transit.

What materials are used for desiccants?

Desiccants are made from:

- Silica gel (porous and moisture-absorbing but lower capacity).

- Calcium chloride (high-absorption, commonly used for industrial shipments).

- Montmorillonite clay (natural, lower-cost, but limited efficiency).

- Molecular sieves (used for specialized applications requiring ultra-low humidity levels).

Vdry Desiccant Bags primarily use calcium chloride for superior moisture protection.

What type of container desiccant should I use?

It is important to consider the risk factors of your shipment and the requirements of your cargo to make the right container desiccant decision.

In some cases high-absorption desiccant packs are the way to go, but in other scenarios a more economical model can be an appropriate option.

What are the risk factors for moisture damage in shipping containers?

Several hard-to-control risk factors contribute to container rain and increase the likelihood of moisture damage inside a shipping container:

- Cargo -The moisture content of your goods contributes to the condensation cycle in the container.

- Temperature -Not only is it impossible to control the weather, but your goods are exposed to conditions that are more extreme than those outside the container.

- Loading conditions -Loading cargo at a location where there is a higher volume of moisture in the air will see a greater relative humidity inside the container. Thus increasing the risk of container rain.

- Position of container on vessel- If your container is exposed to direct sunlight then it will experience a greater range of temperature fluctuations, which influences the risk of container rain.

- Delays at loading/unloading -The most drastic temperature fluctuations occur at loading and unloading, as this is when the containers are directly exposed to the elements. Any delays at this stage of the voyage mean extending the period of heightened risk.

Destination -If your shipment crosses the equator, or moves from one climatic zone to another, the risk of condensation damage will increase. The length of the voyage will also impact on the risk to your cargo.

What is container rain?

When you load a shipping container it is full of moisture. This can be found in the air, the cargo, packaging, pallets and wooden flooring.

As the temperature in the container increases this moisture evaporates into the air, increasing the relative humidity within.

When the temperature falls, this moisture condenses on the cooler surfaces of the container ceiling and walls.

This process of evaporation and condensation inside the container follows the repeated temperature changes between day and night, and is exacerbated by voyages across di erent climatic regions.

The result is container rain, which is when drops of condensation fall on the goods below. This leads to expensive cargo losses.

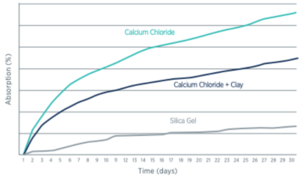

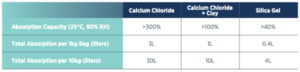

How do different desiccant types compare in absorption capacity?

There are many different container desiccants available on the market, but not all are created equal.

One of the key factors when differentiating desiccants is the absorption capacity, which is based upon the gel mix used in manufacturing.

Because of this shippers opt for calcium chloride desiccants which can absorb up to 300% of their own weight. This is much greater than silica gel which has a capacity of around 40%.

Keep an eye out for models that claim to be calcium chloride-based, but contain very little calcium chloride, as this will lower the absorption capacity.

Think of this as comparing whiskey and beer. Both are alcoholic drinks, but drinking a pint of whiskey will leave you feeling different to how you would have done if you’d stuck with the beer.

How to compare different desiccant options?

A lot of container desiccant suppliers claim that theirs is the best on the market, without anything to back it up.

This is why it is important to make sure that when you’re assessing container desiccant options, that you ask the supplier for quality reports from an independent organization.

These will help you compare desiccants in standardized conditions via a neutral party.

You need to pay attention to key characteristics such as absorption, leak resistance, material quality and non toxicity, and make sure these independently certified.

How much will my desiccant absorb during a shipment?

How much humidity a container desiccant will absorb during a shipment depends on a variety of factors. The main variable is the conditions inside the shipping container during the voyage. In conditions of higher humidity, your desiccant pack will absorb more. In lower humidity scenarios, the container desiccant will absorb less. The bottom line is that your humidity desiccant will absorb as much as is necessary to protect your cargo.

If you want a better idea of how your desiccant will perform, ask your supplier for a quality report in which the absorption is tested in standardized conditions.

Are lower cost container desiccants a good way to save money?

The short answer is no.

Using low cost desiccants means that you need a greater volume of material to achieve the same level of protection as you would with a lower quantity of high-absorption desiccants.

This means greater costs in material spending, as well as the costs in handling, shipping and storage.

Then you need to analyze the cost of increased of cargo damages when using lower cost container desiccants.

How many desiccant bags do I need to use per container?

As we have already seen there are a variety of unpredictable factors that influence the risk of moisture damage to your cargo. So you should always consider variables such as the voyage length and the nature of your cargo.

Then you need to factor in the absorption capacity of the desiccant bag you are using. Packing your container with 10kg of silica desiccants will give you less protection than 10kg of calcium chloride desiccants.

Conversely, 2kg of calcium chloride desiccants will give you more absorption than 10kg of silica gel desiccants.

Understanding this is not only crucial to protecting your cargo, but also in avoiding overspending on unnecessary desiccant material.

How long do desiccant packs last?

The lifespan of desiccant packs depends on factors like container conditions, humidity levels, and the product’s absorption capacity. On average:

- Vdry cargo moisture bags can last several weeks to months, depending on the journey’s duration and moisture levels.

- Regular inspection and replacement after extended use ensure optimal performance.

How do you store desiccant bags?

To maintain effectiveness, desiccants should be stored in:

- A dry, airtight container to prevent premature absorption.

- A cool, low-humidity environment.

- Original packaging until use to prevent early activation.

Improper storage can reduce absorption capacity before deployment.

Where can I buy Vdry Desiccant Bags?

Vdry Desiccant Bags are available through authorized distributors and directly from EPG Industries via our contact page.

For bulk orders or specific requirements:

- Fill out our contact form here to request a quote.

- Call our team to discuss your order +1 786 516 2232

. - Find an authorized distributor in your region.

Related products

CERTIFICATIONS

SGS

ISO

CE

intertek

Certification for safe transport of chemical goods