Cargo desiccants are an essential way to protect goods against moisture damage during shipping.

But with so many desiccant bags for shipping containers on the market, it can be hard to understand which are best for your needs.

In our in-depth guide we outline what key characteristics you should keep an eye out for, and some of the common problems that can arise with subpar container desiccants.

Absorption Is Key When Choosing Desiccant Bags for Shipping Containers

Desiccant bags for shipping containers use an absorbent gel formula to take humidity from the surrounding air.

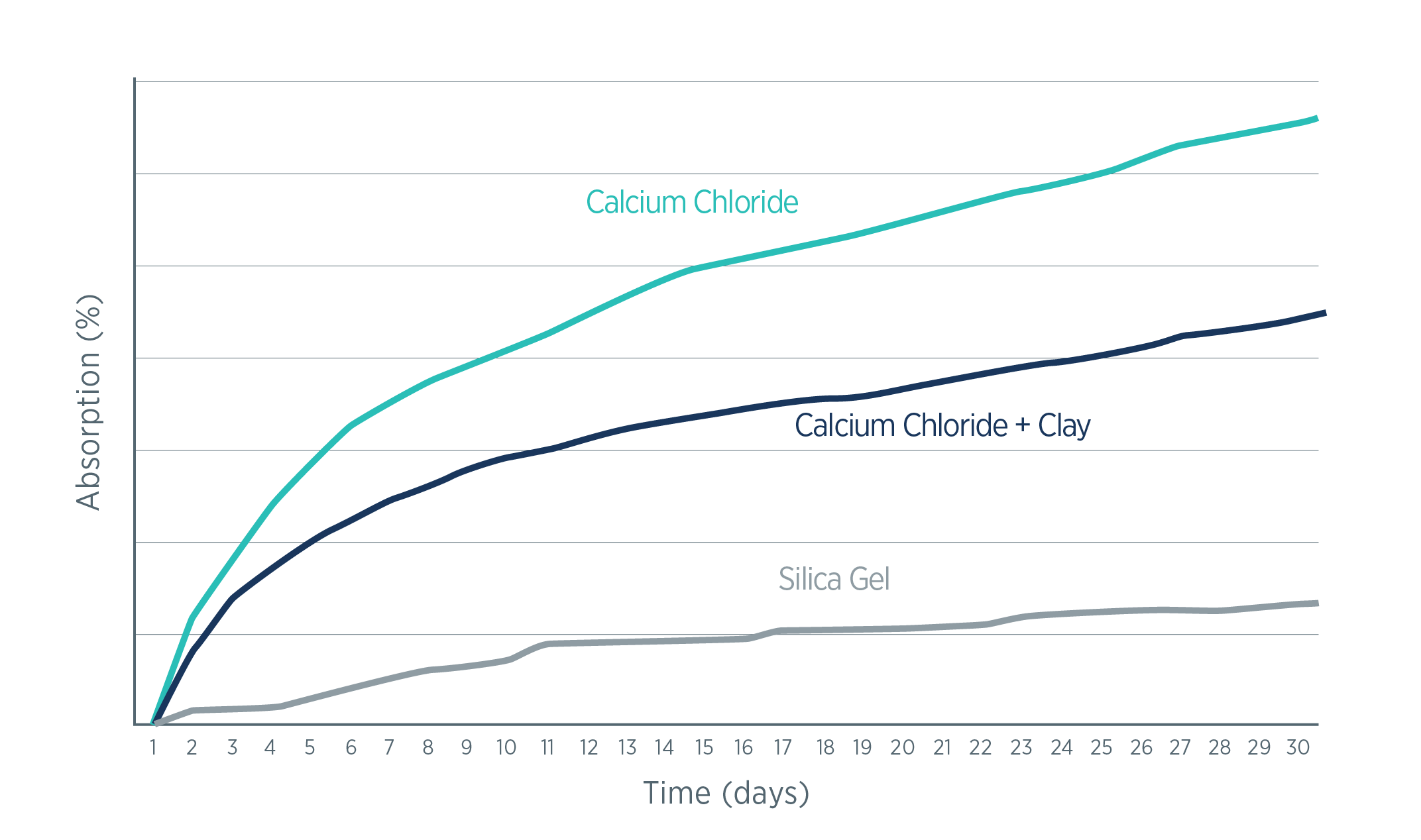

There are a lot of different formulas which impact the capacity and speed of absorption of a given cargo desiccant.

For example, a silica gel desiccant will only absorb approximately 40% of its weight.

Absorbing up to 300% calcium chloride has the greatest capacity on the market.

Container desiccants manufactured with calcium chloride and clay mix will absorb around 100% of their weight.

The extreme conditions of international container shipping mean that calcium chloride desiccants are the go-to choice for many shippers.

Less effective cargo desiccants would not be able to tolerate the large volumes of humidity, the intense nature of the condensation cycle and will reach full capacity before the end of long voyages.

Understanding these factors is not only important in reducing cargo losses, but also in overspending on unnecessary desiccant materials.

What Does Your Container Desiccant Absorb in Real Terms?

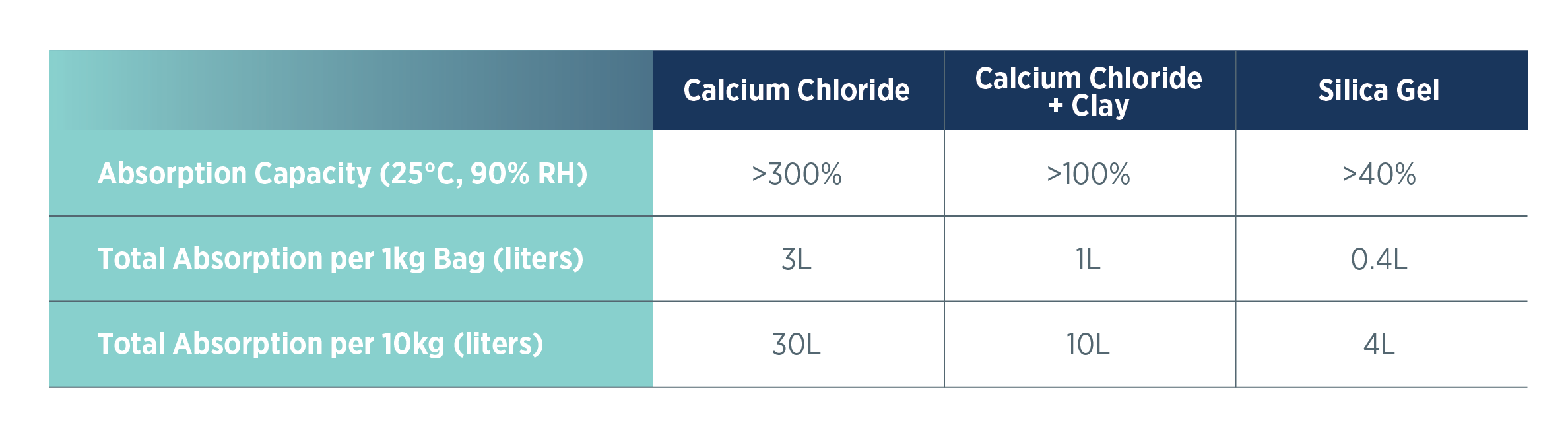

We’ve already seen how absorption capacity can vary widely amongst desiccant bags for shipping containers.

But what does this mean in real terms?

This means that a 1kg calcium chloride desiccant can absorb up to 3 liters of moisture. If you use 10kg of calcium chloride desiccant in a container it will absorb up to 30 liters of moisture in total.

On the other hand, if you use a 1kg silica gel container desiccant it will absorb around 400ml of moisture. To put this into the context of packing a container with 10kg of silica gel desiccants will only absorb around 4 liters in total.

This means that when you are analyzing how many desiccant bags are for shipping containers you should always factor in the absorption capacity.

Understanding this will help you better protect your cargo and avoid overspending on unnecessary cargo desiccants.

But…Not All Calcium Chloride Desiccants Are the Same!

You don’t need to drink alcohol to understand this next analogy.

Both beer and whiskey are alcoholic drinks. But if you were to drink a pint of whiskey you’d feel very different from how you would have done if you’d stuck with the beer.

The same logic applies when comparing desiccant bags for shipping containers. There are many that claim to be calcium chloride-based, but only contain 10% calcium chloride.

This low proportion of calcium chloride minimizes the absorption capacity of the container desiccant.

The Vdry Bag uses 80% calcium chloride. This is why it has one of the highest absorption capacities on the market.

The Importance of Desiccant Gel

So, your cargo desiccant bag has removed humidity from the container atmosphere. Now what?

Well, you might think that is the end of the process, but you’d be wrong. This moisture needs to be converted into a gel with a binding agent.

It might sound strange but some models don’t form a desiccant gel. Instead, they hold the moisture within the bag or pole as a liquid.

While this gives users a nice visual opportunity to understand how much their desiccant has absorbed, this method creates a lot of unnecessary risks.

If this container desiccant were to break or fall during the voyage there would be a high risk of excessive moisture damage to the cargo.

This is why you should always opt for a model with a desiccant gel to ensure your goods are protected in all circumstances.

Is Your Cargo Desiccant Leakproof?

Needless to say, your container desiccant isn’t worth much if it absorbs moisture, only to then leak all over your goods.

Not only will leaking lead to costly damages, but will contribute moisture to the condensation cycle and result in container rain.

This means you should always assess the materials used to manufacture the cargo desiccant pack and check for signs of leakage when unloading the container.

To Wrap Up…What Is Important When Choosing Desiccant Bags for Shipping Containers?

As we have seen in this guide, not all container desiccants are created equal, and there are a lot of key factors to analyze to ensure your goods remain safe and dry throughout shipping:

- Focus on Absorption Capacity: calcium chloride desiccants absorb up to 300% humidity and are the go-to choice for container shipments

- Make Sure Your Desiccant Is Leakproof: subpar desiccant packs will leak moisture on goods and cause costly damages and losses

- Opt for a Desiccant that Converts Moisture into a Gel: by converting moisture into a gel your container desiccant is reducing the risk to cargo