As we have already discussed in our blogs, cargo is regularly at risk of heat damage at various stages of the supply chain.

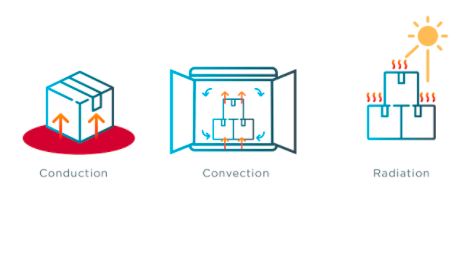

While we have shared some in-depth tips on how to better protect your goods against extreme temperatures and fluctuations, to appreciate the risk to cargo it is important to understand the key types of heat transfer.

The Impact of Solar Radiation During Shipping

Unsurprisingly direct exposure to sunlight is a key source of cargo temperature damage. This can occur regularly at all stages of the supply chain, especially when goods are left on loading docks or runways. In these scenarios, exposure to direct sunlight for even a short period can lead to irreversible cargo damage.

Goods are also exposed to elevated temperatures as direct solar radiation heats the metal walls of shipping containers or trucks. This will create a microclimate as the temperature within is much greater than the ambient conditions outside. This phenomenon means that it is not uncommon to see temperatures within the container reach 50°C.

Shippers can reduce the risk of damages by opting for thermal packing materials that are manufactured with highly reflective materials. Many Temcoat products are manufactured with premium-grade pure aluminum which reflects up to 97% thermal radiation. This is significantly greater to inferior materials which may only reflect around 70% thermal radiation.

Why is Thermal Conduction a Risk to Cargo?

Have you ever seen one of those videos of people frying an egg using the heat emitted from the hood of their car?

If you have, then it shouldn’t be hard to imagine how hot the metal walls of shipping containers or trucks can get when exposed to direct sunlight. The same happens to the asphalt of runways and loading docks.

This means that shippers should take steps to ensure that temperature-sensitive goods don’t come into contact with these elevated heat sources. Just imagine what would happen to your shipment of perishables or pharmaceuticals if they were left on a surface that was hot enough to fry an egg.

As mentioned in the previous section, you should favor products that are highly reflective to minimize the thermal transfer from the hot surface to your goods. Similarly, keep an eye out for solutions that are manufactured with high-grade and resistant materials as these will act as an insulative barrier to protect your cargo. Another effective solution is products that include design features that help create a buffer zone between the goods and the heat source. A buffer zone can be especially important as the transfer of thermal energy is less efficient through the air than it is through a solid.

How to Minimize the Risk of Convection

Convection is the circulation of thermal currents within an air space. This is caused by low-density warm air particles rising and replacing higher-density cool air particles. If these cooler air particles are then warmed up by a heat source the process will repeat.

This leads to an increased risk of damage as cargo that had previously been in a cool space is now surrounded by warmer air. But it is not only exposure to elevated temperatures that is a problem. Thermal convection also leads to damaging temperature fluctuations, as the constant displacement of air particles means that the cargo air space is frequently switching from hot to cold and back again.

Shippers can overcome this problem by opting for thermal packaging solutions that offer hermetic and fully-sealed qualities as this will limit the circulation of air currents in the cargo area. This will mean that goods are kept at stable temperatures and protected from peaks and fluctuations.