We all understand the huge problem of cargo damage caused by shipping container condensation

While cargo desiccants have long been a popular method to overcome shipping container condensation, many shippers are analyzing the impact of temperature fluctuations in an effort to better protect their goods against condensation.

So how does temperature influence moisture damage to cargo? And what steps can you take to prevent this problem?

The relationship between temperature fluctuations and shipping container condensation

It’s no secret that cargo inside shipping containers is frequently exposed to condensation, leading to billions of dollars of losses each year.

This is a result of temperature fluctuations that occur inside the shipping container.

When the shipping container is exposed to direct sunlight, the hot metal walls will raise the temperature inside, often to a level that is significantly greater than the external ambient conditions. The reverse occurs during cooler periods when the temperature inside the shipping container can drop sharply.

These temperature fluctuations can follow the cyclical changes between night and day, and are exacerbated by the nature of international shipping in which goods can be transported between different climatic regions.

During the warm periods of the day moisture evaporates from the cargo into the container atmosphere, raising the relative humidity within.

As the temperature drops the air molecules shrink. This means that the air is unable to hold all the moisture. This leads to condensation forming on the cooler surfaces of the metal container walls and ceiling.

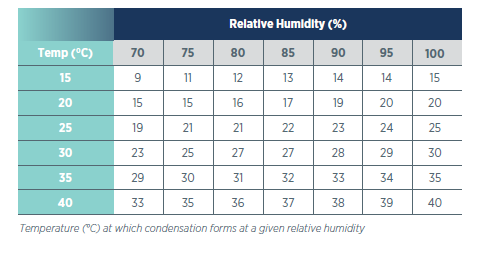

The temperature at which condensation forms is known as dew point. It is dictated by the relative humidity and temperature of the air. The higher both of these factors are, the less the temperature needs to drop for condensation to form.

In the below chart you can see more about when dew point is reached.

These drops of condensation fall onto the goods below, leading to damages in a phenomenon known as container rain. As the temperature shifts occur between day and night, the risk is repeated daily.

How shippers can reduce the impact of temperature fluctuations?

Thermal container liners are a popular way to protect goods against extreme temperatures and fluctuations, such as pharmaceuticals and wine.

These highly-reflective liners interrupt the three main types of heat transfer – conduction, convection, and radiation to minimize temperature fluctuations inside the container.

This means that temperature-sensitive products remain unaffected despite any external climatic stresses.

The method can double up to prevent shipping container condensation. This means better protection in shipments when condensation is a primary concern, such as coffee shipped from tropical regions in South America to cooler climates in Europe or North America.